Investment Return Analysis for DPH260+ZH220 Automatic Blister Cartoning Machine Line:

Investing in the DPH260+ZH220 Automatic Blister Cartoning Machine Line offers a promising outlook for growth and potential investment returns. Here's an analysis of the investment return based on key factors:

Growing Demand for Blister Packaging and Cartoning Solutions: The demand for blister packaging and cartoning solutions is on the rise across industries, including pharmaceuticals, healthcare products, cosmetics, and consumer goods. The DPH260+ZH220 Automatic Blister Cartoning Machine Line caters to this growing demand by providing an integrated and efficient packaging solution. The expanding market for blister packaging and cartoning presents significant growth opportunities for the machine line.

Market Expansion Opportunities: The DPH260+ZH220 Automatic Blister Cartoning Machine Line can explore market expansion opportunities by targeting new industries or geographic regions. As the need for efficient blister packaging and cartoning increases globally, the machine line can penetrate emerging markets and capitalize on industry trends, thereby expanding its customer base and increasing investment returns.

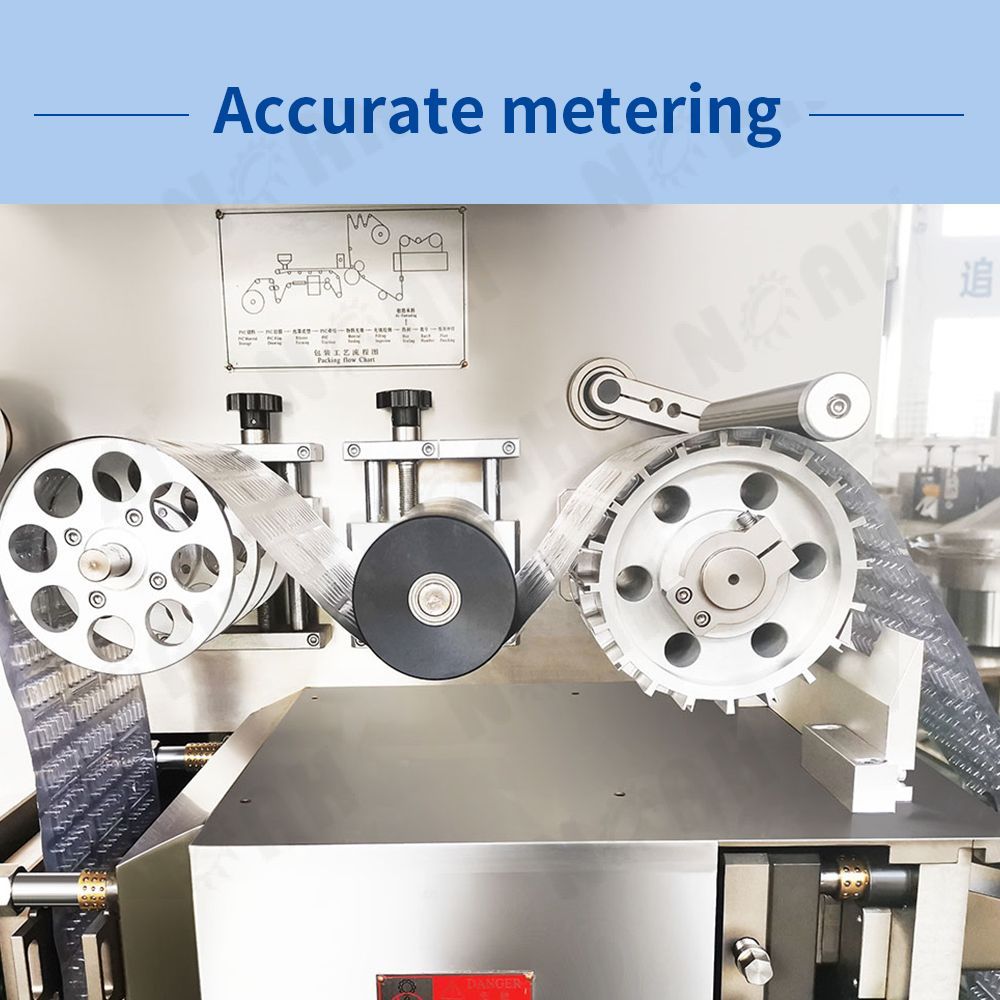

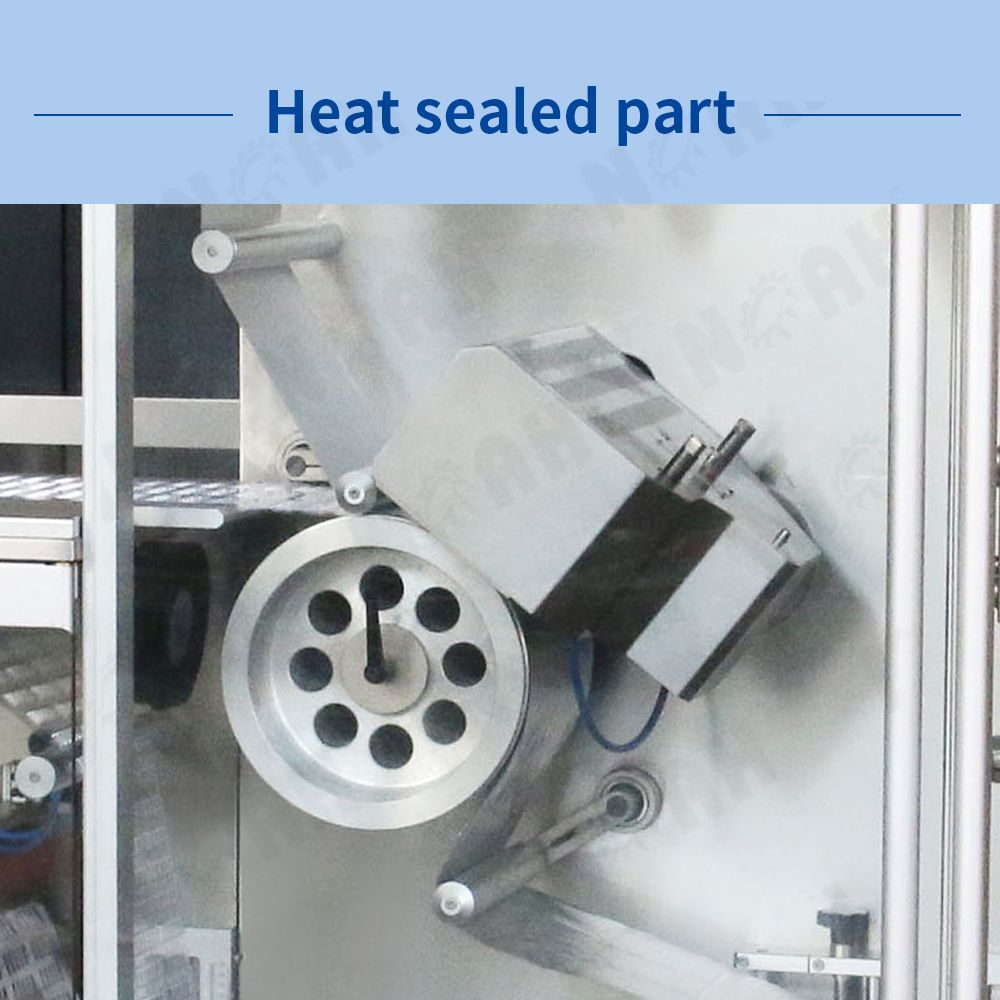

Automation and Efficiency: The DPH260+ZH220 Automatic Blister Cartoning Machine Line significantly improves operational efficiency by automating the blister packaging and cartoning processes. It eliminates manual labor, reduces human errors, and increases packaging speed. The machine line's automation capabilities lead to enhanced productivity, cost savings, and improved profitability, positively impacting investment returns.

Customization and Flexibility: The DPH260+ZH220 Automatic Blister Cartoning Machine Line offers flexibility in adjusting blister sizes, shapes, and carton dimensions, allowing for customization based on specific product requirements. This customization capability enables manufacturers to cater to a wide range of products, meet diverse packaging needs, and adapt to changing market demands, thereby enhancing investment returns.

Integration with Packaging Line Equipment: The DPH260+ZH220 Automatic Blister Cartoning Machine Line can be seamlessly integrated into a complete packaging line, working in conjunction with other equipment such as blister forming machines, labeling machines, and sealing machines. This integration streamlines the entire packaging process, optimizes efficiency, and reduces downtime, positively impacting investment returns.

Compliance with Regulatory Standards: The DPH260+ZH220 Automatic Blister Cartoning Machine Line can be equipped with serialization and track-and-trace systems to ensure compliance with regulatory requirements, particularly in the pharmaceutical industry. This compliance capability enhances the machine line's market value and opens doors to industries with stringent regulatory standards, further improving investment returns.

Technological Advancements and Upgrades: The packaging industry is continuously evolving with advancements in automation, software integration, and machine intelligence. The DPH260+ZH220 Automatic Blister Cartoning Machine Line can leverage these technological advancements to stay competitive and meet evolving customer needs. Regular upgrades and improvements in the machine line's capabilities ensure its long-term value and optimize investment returns.

After-Sales Service and Support: Timely and reliable after-sales service and support play a crucial role in maximizing investment returns. Manufacturers typically provide installation assistance, training, and ongoing technical support for the DPH260+ZH220 Automatic Blister Cartoning Machine Line. A robust support system ensures smooth operation, minimizes downtime, and enhances customer satisfaction, contributing to the overall investment return.

Return on Investment (ROI): The DPH260+ZH220 Automatic Blister Cartoning Machine Line has the potential to generate a significant return on investment. Factors such as market demand, pricing strategy, operational costs, maintenance, and market penetration will influence the exact ROI. Conducting a comprehensive cost-benefit analysis, considering these factors, and projecting sales and operational expenses will provide valuable insights for optimizing the investment return.

Competitive Advantage: By investing in the DPH260+ZH220 Automatic Blister Cartoning Machine Line, businesses can gain a competitive advantage in the market. The machine line's integrated capabilities, automation features, flexibility, and customization options position the investment as a strategic move to differentiate from competitors, capture a larger market share, and achieve higher investment returns.

To further enhance the investment return, it is advisable to engage with industry experts, potential customers, and conduct thorough market research to understand market dynamics, competitive landscape, and emerging trends in the blister packaging and cartoning industry.

Descargar

Descargar