The DPH-360 Roller Plate Blister Packing Machine presents a promising investment opportunity with its strong growth prospects in the packaging industry. Here is an investment return analysis highlighting the potential returns and benefits:

Market Demand: The global demand for blister packaging is on the rise, driven by industries such as pharmaceuticals, food, and consumer goods. The DPH-360 caters to this growing market demand, positioning it for sustained business opportunities.

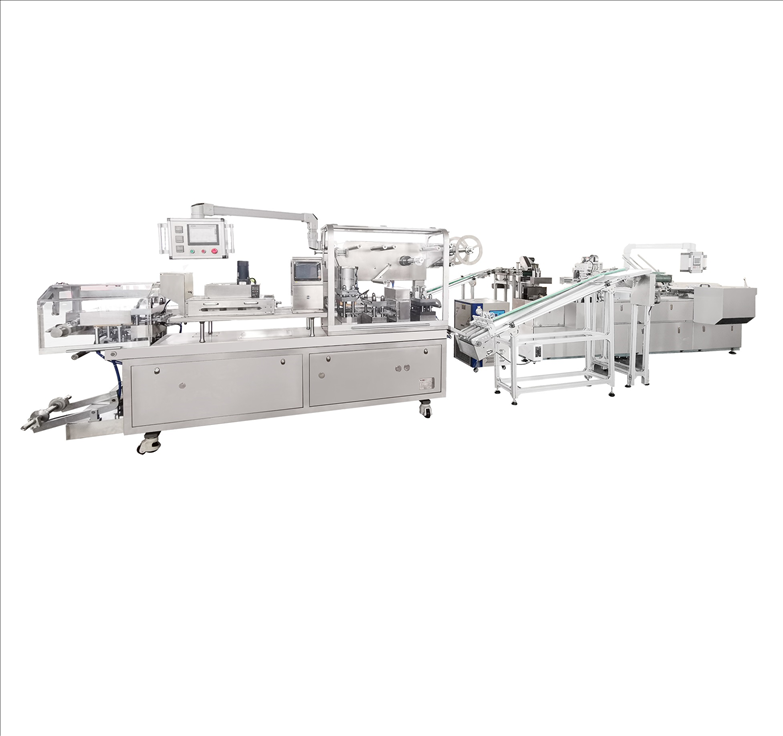

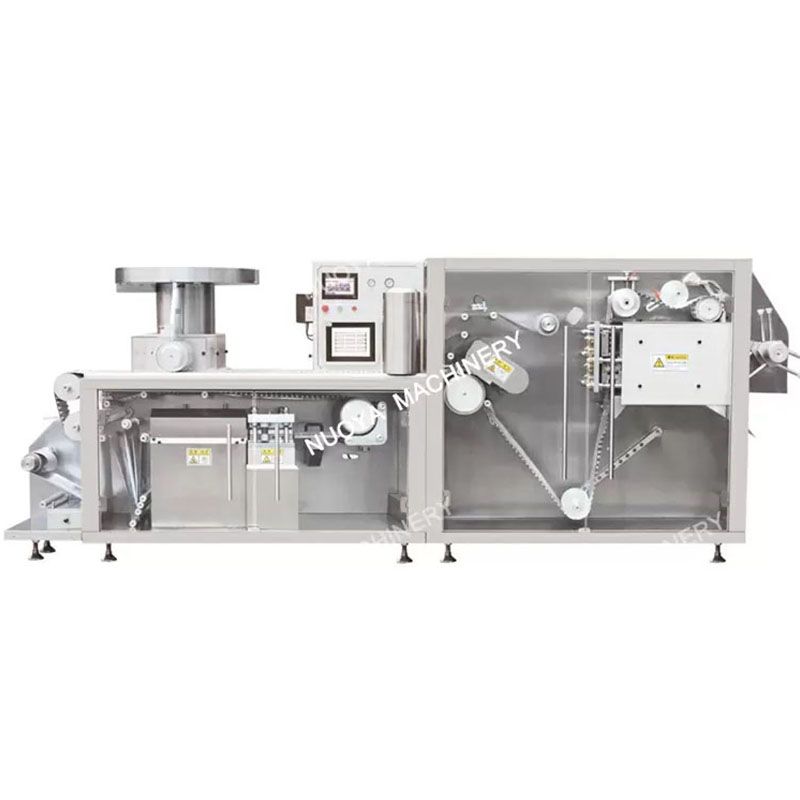

Increased Efficiency: The DPH-360 offers high-speed production and precise blister packaging capabilities. By streamlining the packaging process, it improves operational efficiency, reduces labor costs, and increases overall productivity.

Diversification of Product Range: The machine's flexibility in handling various blister sizes and shapes allows for diversification of products that can be packaged. This versatility expands the potential customer base and revenue streams.

Competitive Advantage: The DPH-360 is equipped with advanced features, such as blister detection and rejection mechanisms, ensuring the delivery of high-quality packaged products. This competitive advantage attracts customers seeking reliable and efficient packaging solutions.

Cost Savings: The DPH-360 optimizes material usage, reducing waste and lowering packaging costs. Its energy-efficient design also contributes to cost savings in the long run.

Long-Term Durability: The machine is built with robust construction and adheres to national standards, ensuring long-term durability and reliability. This minimizes maintenance and replacement costs, resulting in improved profitability.

After-Sales Support: Investing in the DPH-360 comes with comprehensive after-sales support and warranty, providing peace of mind and minimizing potential risks associated with maintenance and servicing.

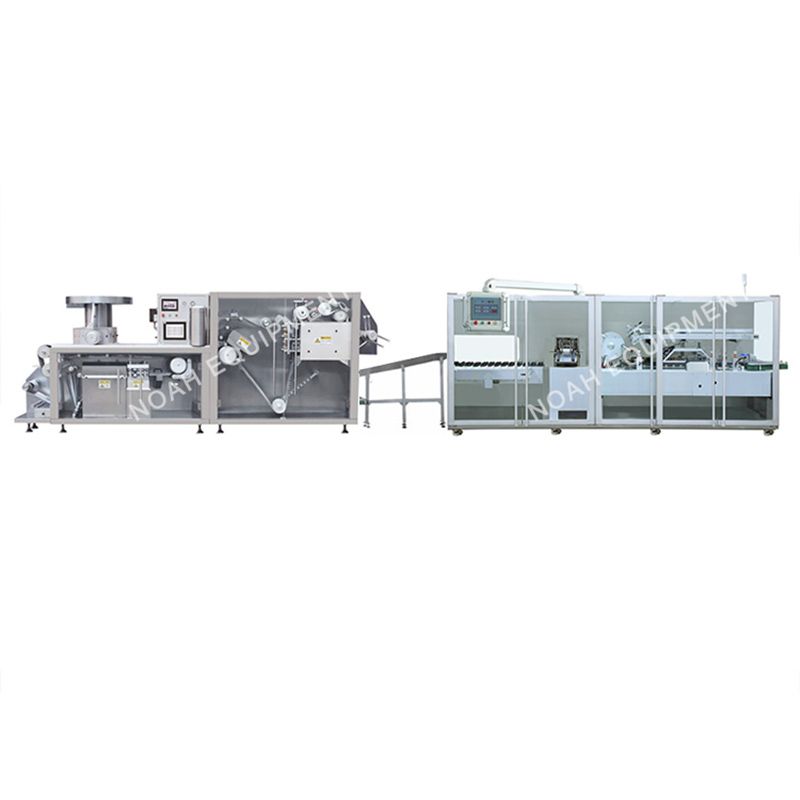

Scalability: As the business expands, the DPH-360 can be integrated with other packaging equipment, creating a complete and efficient production line. This scalability allows for future growth and increased profitability.

Considering the strong market demand, operational efficiency, cost savings, and competitive advantages, investing in the DPH-360 Roller Plate Blister Packing Machine presents a favorable return on investment. It not only generates immediate returns through increased productivity but also offers long-term growth potential in the dynamic packaging industry.

Descargar

Descargar